Mecanizado eficiente en condiciones de lubricación criogénica de la aleación Ti48Al2Cr2Nb (Ti-ECOMACHINING)

Datos

Proyecto/ayuda interna de investigación UCLM 2022-GRIN-34346 (2023-2025).

Investigadores principales: Valentín Miguel Eguía y Enrique García Martínez

Presupuesto: 17.900,00 €.

Descripción del proyecto

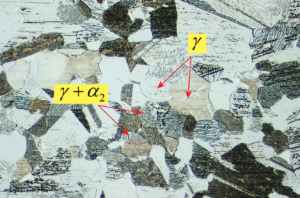

Se observa en los últimos años un crecimiento relevante en la investigación y aplicación industrial de los aluminuros de titanio, con mayor relevancia en los sectores aeroespacial y automovilístico, debido a su menor densidad y excepcionales características mecánicas resistentes a elevadas temperaturas. Sin embargo, este material presenta grandes dificultades para el mecanizado debido a su alta dureza y fragilidad, baja conductividad térmica y gran reactividad química. Estas propiedades aumentan los fenómenos de fricción entre viruta y herramienta, causando un desgaste excesivo de ésta y generando graves daños superficiales en las piezas mecanizadas. El presente proyecto consiste en la investigación para la mejora y optimización de las condiciones de mecanizado de los aluminuros de titanio, aplicando la investigación a la aleación Ti48Al2Cr2Nb, con mayores expectativas potenciales en la actualidad. Para ello, la propuesta se centra en el mecanizado por torneado con lubricación criogénica, determinando la función de desgaste de la herramienta de corte, estableciendo la afección del proceso sobre la pieza mecanizada, optimizando las condiciones de corte y evaluando las condiciones económicas del proceso. Uno de los aspectos más novedosos es que se va a desarrollar una metodología de análisis del efecto de las vibraciones durante el mecanizado basado en la medición de redondez de las piezas mecanizadas y en el análisis de la señal correspondiente. Todo lo indicado permitirá situar el proceso de torneado de los aluminuros de titanio en el rango de viabilidad industrial, en el que todavía la técnica no se encuentra.

Objetivos del proyecto

En el proyecto se plantea profundizar en la aplicación de la técnica de lubricación criogénica a partir de nitrógeno líquido en el proceso de torneado de la aleación de aluminuro de titanio Ti48Al2Cr2Nb, con el objetivo general de posibilitar la viabilidad industrial de los procesos de mecanizado para este material. Para ello, se plantean los siguientes objetivos fundamentales:

- Determinar la eficiencia de la lubricación criogénica en el desgaste de la herramienta de corte para condiciones de mecanizado con aplicación industrial.

- Eliminar las alteraciones superficiales y subsuperficiales de las piezas mecanizadas.

- Obtener las condiciones de corte y lubricación óptimas en términos económicos para el torneado de

aluminuros de titanio.

Publicaciones derivadas de la investigación

A new model to predict the tool life in turning of titanium aluminides

Enrique García-Martínez, Valentín Miguel, Alberto Martínez-Martínez, Jorge Ayllón Pérez

The International Journal of Advanced Manufacturing Technology, 2024, 125, Springer, 10.1007/s00170-023-11090-0

Abstract

Several tool wear models for machining operations have been reported in the literature. However, most of them are capable of modeling only a part of the wear curve, designed for quasi-linear curves or need to be fitted by means of differential equations. In this research, a new analytical easy-to-use wear model is proposed, taking into consideration the geometry of the cutting insert and the influence of the cutting speed and the tool-workpiece contact stress. In addition, the effect of the critical machining time, relative to the tool degradation, has also been introduced. The wear model describes completely the wear curve, from the initial rapid wear stage to the thermal-activated wear rate acceleration. The constants and parameters of the equation are determined by cutting experiments from the cutting forces and flank wear registers under a variety of technological parameters. This model has been validated for turning process on Ti48Al2Cr2Nb aluminide with uncoated carbide tool under different cutting conditions, varying the cutting speed and the geometrical position of the tool. It has been demonstrated its suitability to predict tool life, according to a defined wear criterion.

Determination of cost-effective machining strategies for rough pocket milling of aluminum by computer-aided manufacturing

Enrique García-Martínez, Valentín Miguel, Ángel Mancebo, Alberto Martínez-Martínez,

Advances in Science and Technology, 132, 176-183, 2023, 125, Trans Tech Publications, https://doi.org/10.4028/p-2kdOtW

Abstract

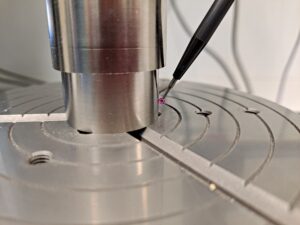

Pocketing is one of the most important operations in the machining of complex parts. This milling process usually consumes a large part of the total machining time, especially if an extensive quantity of material is involved, determining the efficiency of the process. This paper studies the influence of the machining strategy and cutting conditions, and the geometry of the pocket on the machining time and cost when milling AW2007 aluminum alloy. For that purpose, a combined methodology based on experimental tests and CAM simulation is proposed. Cost analysis, which represents the main novelty of the research, takes into consideration, properly, the cutting time required to complete the pocket, the tool life, the tool change time and some economic factors such as power and tool costs. Spiral, curvilinear, parallel and zig-zag machining paths, along with seven different pocket geometries, are considered. Parallel and curvilinear milling trajectories have been found as the most cost-effective strategies. The efficiency of the parallel strategy increases with respect to the others as the geometry of the pocket becomes less compact, i.e., it is defined with a higher shape factor. According to the experimental tests and cost results, the machining operation should be performed with the highest feed rate, axial depth and cutting speed of the experimented values, 0.2 mm/tooth, 10 mm and 200 mm/min, respectively.

Evaluation of machining-induced chatter and part quality in tial alloys turning processes by means of harmonics analysis

Enrique García-Martínez, Valentín Miguel, María Carmen Manjabacas, Juana Coello, Maria Crina Radu

Advances in Science and Technology, 959, 149-158, 2023, 125, Trans Tech Publications, https://doi.org/10.4028/p-EfUcv8

Abstract

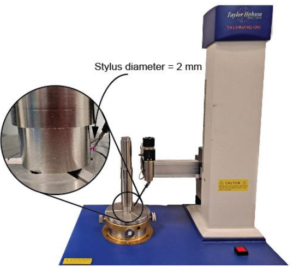

Titanium alloys have been reported as potential materials for aeronautical and automotive applications due to their interesting mechanical properties, combined with their low density. The manufacturing processes developed for these alloys require finishing machining operations to improve the surface quality of the parts and to meet the desired geometrical tolerances. Nevertheless, titanium aluminides exhibit extremely low machinability in comparison to traditional titanium alloys. The combination of the low thermal diffusivity of these materials and the high chemical affinity and friction coefficient with the cutting tools accelerate tool wear phenomena and lead to a deterioration of the part surface quality. Moreover, the mechanical properties of titanium aluminides contribute to increase the cutting forces which generates tool repulsion resulting in undesirable vibration or chatter phenomena. In this paper, the machining suitability of the turning process of Ti48Al2Cr2Nb titanium aluminide has been evaluated based on the analysis of chatter phenomena and the inspection of the surface roughness and roundness tolerance of the machined part. Experimental turning tests have been carried out by varying the main parameters of the process, cutting speed, feed rate and tool geometry, with the objective of determining the best cutting combination. For this purpose, a harmonic analysis methodology of the roundness profile based on the application of the discrete Fourier transform (DFT) has been employed. This technique has made it possible to isolate the vibration-induced machining effects from the lower frequency defects generated by part bending and to relate them to the surface quality and geometrical accuracy of the machined part.

Economic analysis of eco-friendly lubrication strategies for the machining of ti48al2cr2nb aluminide

Enrique García-Martínez, Valentín Miguel, Alberto Martínez-Martínez

Journal of Cleaner Production, 2024, 435, Elsevier, https://doi.org/10.1016/j.jclepro.2023.140541

Abstract

Titanium aluminides have been identified as potential materials in the aeronautical sector. However, the high processing costs and their low machinability limit their application. This research evaluates the effectiveness of minimum quantity lubrication technique (MQL) and cryogenic lubrication on the turning process of Ti48Al2Cr2Nb aluminide from an economic and industrial productivity point of view, with the aim of determining the optimum cutting conditions to reduce manufacturing costs and maximize the production rate. To this end, a preliminary experimental analysis will be carried out, determining the tool life as a function of the cutting speed for each lubrication condition (dry, MQL and LN2). The results show that, although both MQL and LN2 conditions allow the tool wear to be reduced, the MQL technique stands out for its higher efficiency and for the possibility of reaching a higher cutting speed. In addition, the high cost of liquid nitrogen implies a 47% additional cost. Consequently, this research finds out that the turning process should be carried out in the cutting speed range of 70–76 m/min under MQL conditions to obtain the highest profit rate.

Effect of minimum quantity of lubricant on carbide tools and surface integrity in the machining of titanium aluminides

Enrique García-Martínez, Valentín Miguel, Alberto Martínez-Martínez

Metals, 2024, 14 (4) 399, Mdpi, https://doi.org/10.3390/met14040399

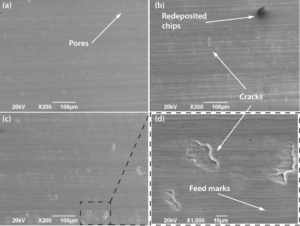

Abstract

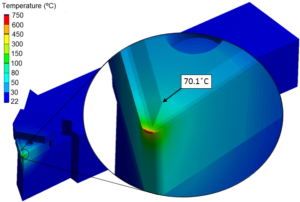

Titanium aluminides are being explored as potential materials for the aeronautical sector. However, their application is limited by the high costs of processing and their difficulties in machining. This research evaluates the effectiveness of the minimum quantity lubrication technique (MQL) on the turning process of Ti48Al2Cr2Nb aluminide in terms of tool wear, tool life, cutting forces, surface integrity, and temperature. It was found that MQL conditions can improve the process efficiency, reducing the thermally induced wear mechanisms and enlarging the tool life compared to dry machining. Furthermore, it allows the cutting speed to be incremented, leading to lower processing times. However, MQL seems to not be effective in the reduction of the strain-hardening effect near the machined surface and, although the number of microcracks is reduced, defect-free surfaces cannot be obtained. Moreover, similar microstructural alterations as for dry cutting were detected. The best cutting conditions in terms of surface quality were assessed using the central composite face (CCF) design and surface response methodology. Optimization of the surface roughness under industrially viable cutting conditions was achieved with an average surface roughness value, Ra, of 0.29 µm (feed rate of 0.05 mm/rev, a cutting speed of 54.6 m/min and a depth of cut of 0.125 mm).